Understanding the Use of a Micrometer: Measuring Depth or Size of an Object

Need Help?

[quform id="1" name="Schools Form"]Table of Contents

Introduction

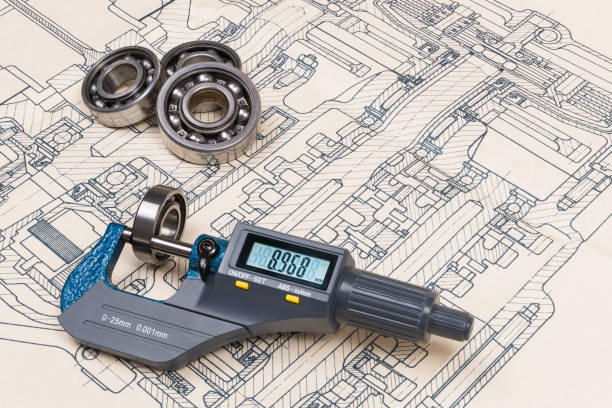

A micrometer, also known as a micrometre, is a precise measuring instrument used in various fields like manufacturing, engineering, and science. This tool is vital in obtaining accurate measurements of the depth or size of objects down to the micron level. The ability to gauge such precise dimensions is crucial for quality control and precision engineering. Here, we’ll explore the method by which a micrometer is used to determine the depth or the size of an object, focusing on two main types: outside micrometers and depth micrometers.

The Method by Which a Micrometer is Used to Determine the Depth or the Size of an Object

The method by which a micrometer is used to determine the depth or the size of an object involves precise measurements using specific types of micrometers. For measuring the outside dimensions like diameter or thickness, an outside micrometer is used, while for measuring the depth of holes, slots, or recesses, a depth micrometer is utilized. The process includes cleaning the object and micrometer, adjusting the micrometer, placing the object between the anvils or lowering the rod into the hole, tightening or locking the measurement, reading the measurement, and repeating if necessary to ensure accuracy. There’s no specific name for this method; it’s simply the process of using a micrometer to gauge the dimensions of an object.

Outside Micrometers

Outside micrometers are used to measure the outside dimensions of an object such as the diameter or thickness. Here’s how it works:

- Clean the Object and Micrometer: Ensure both the object and micrometer’s measuring faces are clean to avoid errors.

- Adjust the Micrometer: Turn the thimble until the faces of the micrometer are just touching.

- Place the Object between the Anvils: Carefully place the object between the two measuring faces (anvils).

- Tighten the Thimble: Turn the thimble until it makes firm contact with the object without over-tightening.

- Read the Measurement: Record the reading from the scale, taking note of both the main scale and the rotating thimble scale.

- Repeat if Necessary: To ensure accuracy, repeat the process and average the measurements.

Depth Micrometers

Depth micrometers are used specifically to measure the depth of holes, slots, or recesses. The process is slightly different:

- Clean the Surface and Micrometer: Wipe off any dirt from the object’s surface and the micrometer’s tip.

- Set the Base on the Surface: Place the base of the depth micrometer on the surface around the hole or recess.

- Lower the Rod into the Hole: Carefully lower the measuring rod into the hole until it reaches the bottom.

- Lock the Measurement: Use the lock on the micrometer to secure the measurement.

- Read the Measurement: Record the reading from the scale, again considering both the main scale and the rotating scale.

- Repeat if Necessary: For accuracy, repeat the process and average the measurements.

Conclusion

The micrometer’s utility in measuring the depth or size of an object is central to various industries that require precision. Understanding how to use both outside micrometers and depth micrometers is essential for professionals working with intricate details and stringent quality control. The process involves proper handling, accurate reading, and awareness of the different parts of the instrument. With proper care and understanding, micrometers can be incredibly valuable tools in the pursuit of exactitude in measurements. Whether in South Africa or elsewhere, these methods remain universal, ensuring the consistency and quality of products and structures.